Electric Powered Scaffold - 108" High

- Details

Tap Image To Zoom

Tap Image To Zoom

Expand description

Expand descriptionThis 500 lbs capacity Electric Powered Scaffold features an adjustable height reaching up to 108” high and the platform is spacious enough for two or more people to work on at the same time. Note that this has only power drive not lift. It is definitely a must have for any material handling industry operated by electricians, construction workers, painters, maintenance personnel and other workers found in schools, hospitals ,office buildings, warehouses, construction sites and many more!

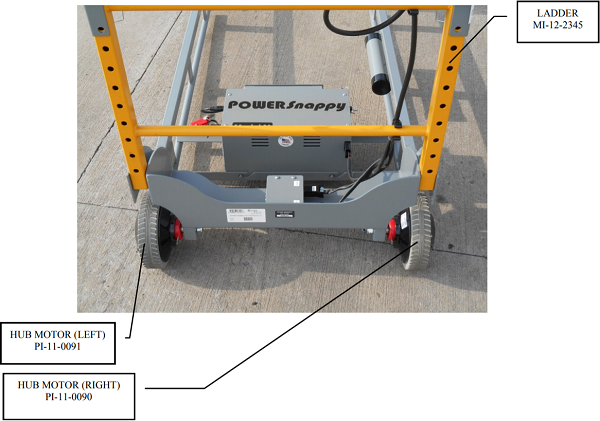

This Motorized Scaffold is equipped with two sturdy 8” drive wheels with additional 5” swivel casters that provide great stability and maneuverability giving you a peace of mind when working on top of the platform. Move from floor to floor on multi-story buildings via elevator, and drive it right on through doorways. Something not possible to do with a scissor lift.

It is powered by two heavy duty and environment-friendly electric 24V hub motors which gives off no emission and negligible noise. It is packed with lots of safety features such as the integrated lock-out switch, auto locking brake system, soft start and stop and complete guard rails. G-pin and snap pin technology secures the arm braces on the power snappy.

That’s not all, the Electric Powered Scaffold’s parts are all removable which makes it easy to store or pack into a truck to be transported to wherever you need it to be. Move from floor to floor on multi-story buildings via elevator, and drive it right on through doorways. Something not possible to do with a scissor lift.

Also Available In:

Standard Features:

- Powerful electric motor driven by two 24V hub motors, one on each wheel. Each motor is rated at 6,000 hrs of use.

- Manpower is enhanced over stepladders and standard scaffold in many cases by reducing the time wasted by moving devices and climbing up and down.

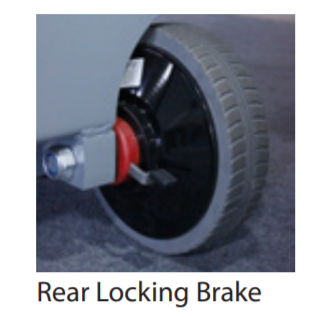

- Integrated brake system with an auto-locking mechanism which triggers when the scaffold’s throttle is turned off.

- Powered by two 12V sealed AGM 35 Amp-Hour batteries power the unit. AGM batteries feature the latest in battery technology and provide exceptional life lasting you up 2 to 3 days of regular use.

- Includes a fast and efficient on board charger and can easily be charged via the built in electric inlet. Simply plug it into a 110V wall outlet.

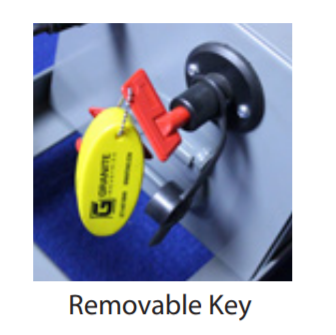

- Equipped with an integrated lock-out switch which ensures proper use by qualified individuals and also adds to the security of the unit at the job site.

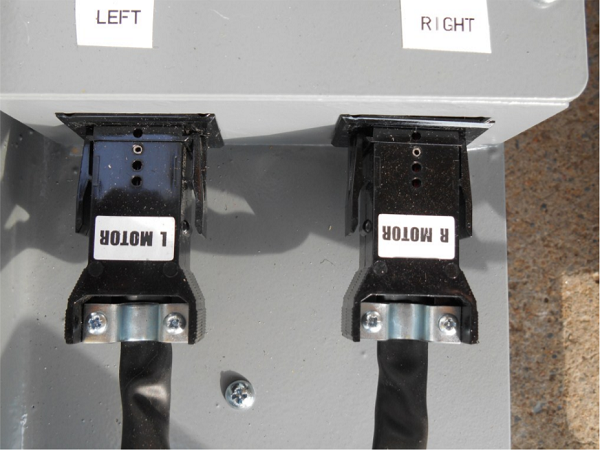

- Industry standard Anderson Power Products connectors are used to ensure secure electrical connections with quick disconnect capabilities

- Complete guard rails are provided and open at both ends for easy boarding access.

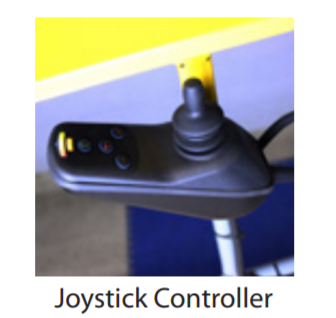

- Custom joystick steering has adjustable speed control. In addition, soft start/stop are provided for safer operation. The joystick also includes built in error lights for quick and easy trouble shooting.

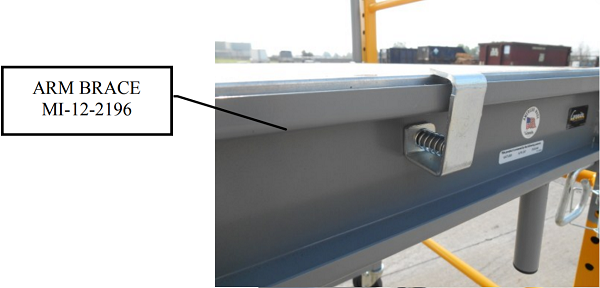

- Adjustable g-pin and snap pin technology secures the arm braces on the power snappy.

- Made in the USA

- Removable extensions and outriggers

- Gear box is enclosed for safety and protection

- Powder coated exterior frame for added durability and resistance

- Comes with heavy duty 8″ Drive Wheels paired with 5″ Swivel Casters on outrigger

- Includes a 1 year warranty on Powertrain & Electronics and an outstanding 3 year warranty on Scaffold & Chassis

Overall Specifications:

- Load Capacity: 500 lbs

- Scaffold Size with Outriggers (Width x Length): 57″ W x 80″ L

- Scaffold Size without Outriggers (Width x Length): 31″ W x 60″ L

- Adjustable Height: 72”-108”H (adjustable every 2”)

- Weight: 475 lbs

Electric Powered Scaffold - 108" High - Reviews

There are no reviews for this product.

- Specs

- Q & A

Are the battery packs removable?

Yes, the battery pack on the Power Snappy is removable. It is a quick release system that does not require tools.

Is this OSHA approved?

the Electric Powered Scaffold meets required OSHA Standards for every state apart from California. The list of standards is as follows:

- Scaffold casters and wheels shall be locked with positive wheel and/or wheel and swivel locks, or equivalent means, to prevent movement of the scaffold while the scaffold is used in a stationary manner. - 29 CFR 1926.452(w)(2)

- The surface on which the scaffold is being moved is within 3 degrees of level, and free of pits, holes, and obstructions. - 29 CFR 1926.452(w)(6)(i)

- The height to base width ratio of the scaffold during movement is two to one or less, unless the scaffold is designed and constructed to meet or exceed nationally recognized stability test requirements. - 29 CFR 1926.452(w)(6)(ii)

- When power systems are used, the propelling force is applied directly to the wheels, and does not produce a speed in excess of 1 foot per second (.3mps). - 29 CFR 1926.452(w)(6)(iv)

- No employee is on any part of the scaffold which extends outward beyond the wheels, casters, or other supports. - 29 CFR 1926.452(w)(6)(v)

- Platforms shall not extend outward beyond the base supports of the scaffold unless outrigger frames or equivalent devices are used to ensure stability. - 29 CFR 1926.452(w)(7)

- Before a scaffold is moved, each employee on the scaffold shall be made aware of the move. - 29 CFR 1926.452(w)(10)

How do you assemble it?

The Electric Powered Scaffold will ship in a wood crate, and will require some assembly. It has a very simple design and is quite easy to assemble by following these simple steps:

- Remove all the shipping components and set base unit on a level surface.

- Rotate both ladders up to a vertical position so arm braces can be added. Pull back the G-pins on the arm brace and engage the “U” channel over the frame leg. Then release the G-pin and slide the arm brace up or down on the frame leg until the pin snaps into a hole. Repeat for the other arm brace. Make sure both arm braces are positioned at the same level. Be sure the platform hold down devices are turned out of the way.

- Lay platform onto the two arm braces making sure the holes in platform line up pins on the arm braces. Turn the platform hold down devices so that they “trap” the platform onto the braces.

- For additional security insert 2”snap pins through the “U” channel and frames after the platform height has been properly set.

As for the Guardrail Installation:

- Insert the 4 bottom guard rail posts into the square sockets on the arm braces and pin in place with the hinge pins. Next, insert the side guard rails into the guard rail posts and insert bolts to secure in place. Note location of the joystick controller guard panel.

- And finally route the power cords to their designated places.