Dockboard Selection Guide

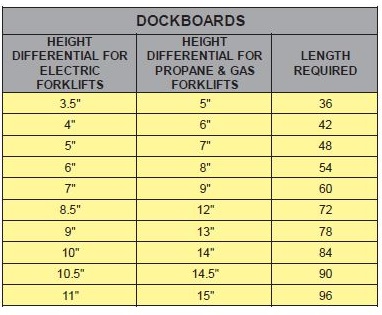

Dockboards are intended to be used for loading and unloading trucks with electric forklifts, propane forklifts, and gas forklifts.

Dock boards are available in aluminum or steel. The steel side curbs give these dock boards their extra weight capacity. The aluminum dockboards have a weight capacity ranging from 10,000 lbs to 15,000 lbs while the steel dock boards have a weight capacity ranging from 15,000 lbs all the way to 60,000 lbs (custom orders available with up to 100k capacity).

Should I Buy an Aluminum or Steel Dockboard?

Aluminum dockboards have the benefit of being lightweight and are ideal for infrequent use, where ease of mobility is key. They tend to get worn out quicker than their steel counterparts, so it is advised to use them in situations where they are only required infrequently. They are avilable with a limited weight capacity of 15,000 lbs.

Steel dockboards, while heavier, have the benefit of being heavier duty and are designed for constant use. The weight capacities on these run up to 60,000 lbs (100k custom orders also possible).

Another benefit of the steel models are that they are available, with what we call the Deluxe Design. This practical upgraded design includes many benefits: Beveled edges at both the entry and exit points, Two 12” long pin pockets at each end of the board with locking pins to secure dockboard in place, this allows for limited below dock applications of up to 2-3 inches. They also feature side curbs are that are angled and tapered to guard against forklift tire damage, as well as fork pockets which make maneuvering them safe and easy.

Universal Design with Forkpockets, Douple Pins, and Beveled Sideguards

Economy Steel Dockboard with Chain Lifters

Please Note: All dockboards are designed to be used in situations where the truck you are unloading is taller than your loading dock,

(not vice versa). For 3 wheel forklifts, it is recommended to use only a steel dockboard.

Selecting Your Length

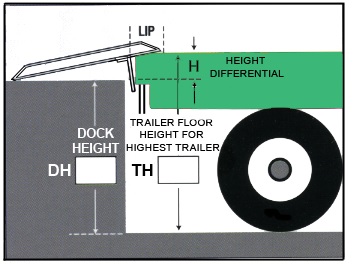

In order to determine the proper length of a dock plate you will require, start off by figuring out your height differential. Height Differential equals:

Height of the highest trailer (TH) minus the dock height (DH) which equals the height differential(H). The chart will tell you, based on the equipment you are using, the required length.

TH______________ - DH________________=H_____________

Selecting Your Width

We recommend a dockboard width of at least 12” wider than the overall width of the equipment or pallet used. Wider boards increase maneuverability and decrease accidents.

Selecting Your Weight Capacity

The minimum weight capacity required for dockboards being used for forklifts, is 3 times the maximum weight capacity of the forklift. This is because the we need to take into account the weight of the forklift with the counterbalance weights that it contains.

Click here to view all of our dock boards.

Also check out our other Selector Guides: