Sky Hook Compact Jib Steel Crane

- Details

Tap Image To Zoom

Tap Image To Zoom

Expand description

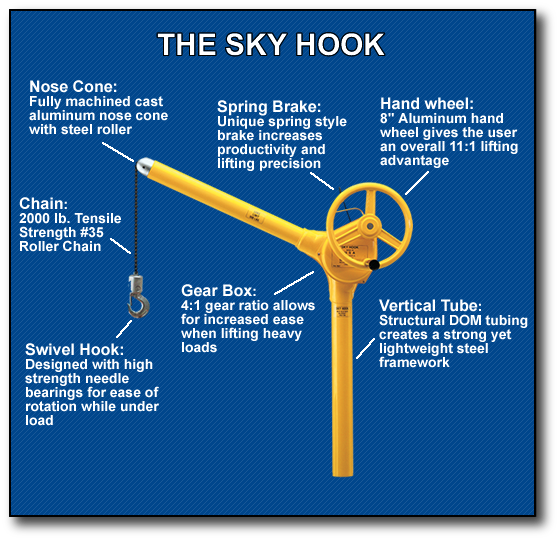

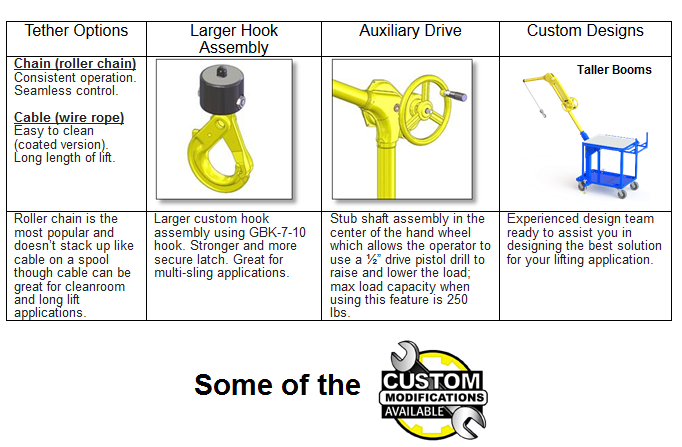

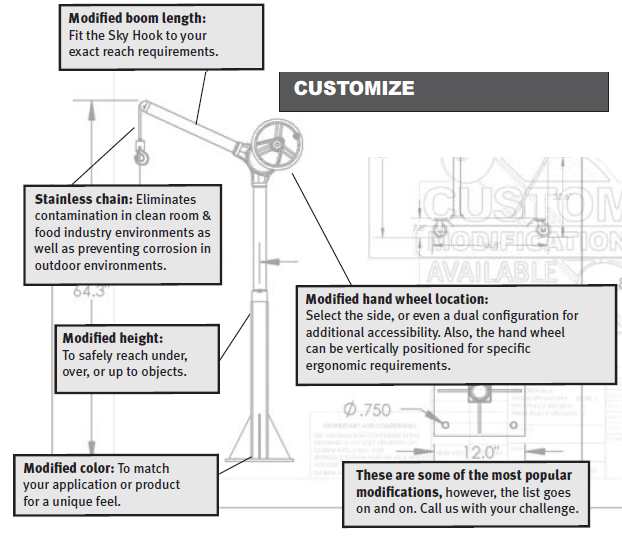

Expand descriptionThe Sky Hook Compact Model Lifting Device is a Compact and Lightweight Jib Steel Crane -It weighs only 23 lbs, making it very easy to move from place to place. It comes with a base designed to fit with your specific tool holder (tool holder not included). See the Model Selection chart below for the correct model # for your needs. You may also purchase the 8500-00A adaptor, if you do not have a quick change tool holder.

The Sky Hook Compact Steel Crane is available in 4 different models:

8500 Economy - Lever Operated Friction Brake with Roller Chain

8700 Premium - Loadlock Clutch Brake with Roller Chain

9500 Economy - Lever Operated Friction Brake with 3/16" Cable

9700 Premium - Loadlock Clutch Brake with 3/16" CableThis unit will prevent back injuries and is ideal for lifting chucks, vises and large pieces of material onto lathes, mills, benches and other equipment. Weighing only 23 lbs, this Sky Hook Model pivots 360° for precision positioning.

Safe and simple to use, this model easily lifts up to 500 lbs. With a base designed for your specific tool holder, its one-handed operation does the work of four people in a single step.

Less expensive than a forklift, overhead crane, or chain hoist, Sky Hook Model Compact Series is a safe lifting solution that answers almost any need. User friendly and adaptable, it makes the job of rotating and positioning a 500-lb. object turnkey.

Easily detached and carried to different locations, this practical, adaptable, labor-saving lifting device is ideal for all general applications. For specialty applications, custom units of Sky Hook Compact Model Series are also available.

The Compact Sky Hook is available with a friction style brake or the clutch style brake, see the Q & A tab above for the benfits of each one. Both models features an easy to use hook system, allowing you to attach it directly to you load, or to use it with one of our popular add on accessories (see below). We can also customize these units, see detailed images above for details.

Also Available In:

- 42.3" Tall Portable Jib Crane With Articulating Arm (21-36" Reach)

- 42.3" Tall Portable Jib Crane With Bolt Down Base and 21" Reach

- 64.4" Tall Portable Jib Crane With Floor Mount and and 21" Reach

- 64.4" Tall Portable Jib Crane With Floor Mount and Articulating Arm (21-36" Reach)

- 63.8" Tall Portable Steel Crane With Vehicle Hitch Base and 21" Reach

Features & Benefits:

- Designed to fit most quick-change tool holders

- Prevents lifting injuries

- Uses one hand operation that does the work of 4 people

- Safely lift & position up to 500 lbs. (227 kg) with one person

- Rotates 360°

- Designed for precision positioning

- Operates in tight working conditions

- Is totally maintenance free

- Has removable boom for easy transport

- Meets applicable O.S.H.A. requirements

Specs:

- Load limit 500 lbs. (227 kg)

- Weighs 23 lbs. (10.4 kg)

- Pivots 360°

- 55” (139.7 cm) Length of lift

- Overall height of Sky Hook including base is 25.8” (65.5 cm)

- One rotation of hand wheel = approx. 1” (2.5 cm) of vertical lift

- Models to fit most quick change tool holders

- Easily detached and carried to different locations

- Constructed of high-strength steel

Optional Accessories:

- Vise Hook - Safely and easily lift your vise. Takes the strain out of removing your vise from your mill every time you need to change your setup, Designed to lift a 6-10" vise jaw.

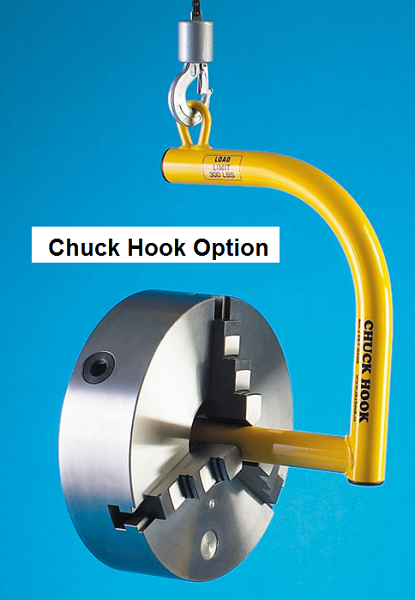

- Chuck Hook - The safest and easiest way to handle your chuck Just tighten the jaws against the Chuck Hook and lift. No slings to slip off; no drilling or tapping needed. Capable of handling up to a 20" chuck or 300 lbs

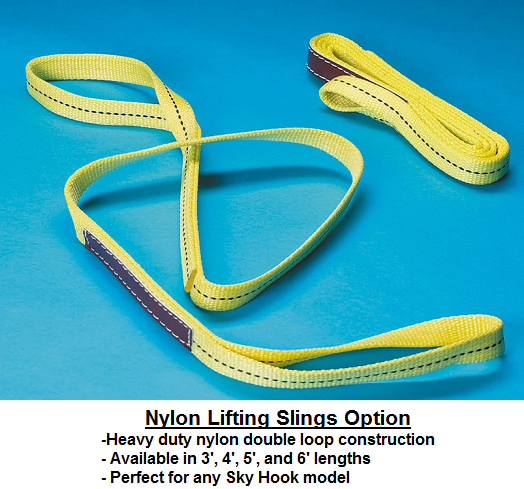

- Nylon Lifting Slings - Heavy duty nylon double loop construction. Available in 3', 4', 5', and 6' lengths.

- Choker Collar - Reduce the lifting reach of your Sky Hook for custom lifting applications. Allows for operation in tight working conditions

- Bolt Down Adaptor - Allows you to install the Sky Hook if you do not have a quick change tool holder

Sky Hook Compact Jib Steel Crane - Reviews

Average customer rating:

Only those who bought this product are allowed to add review

If you've already bought this product, please sign in and add your own review!

1 Most recent customer reviews (see all reviews): - Q & A

What is the difference between the chain and cable lifts?

All the Sky Hook models are available in either roller chain or cable configurations. Each configuration has unique benefits and are best suited for the appropriate lifting application.

The Steel Roller Chain option provides a consistent travel rate and precise load positioning. Cables on the other hand stack up on the spool, requiring a slightly more amount of force as the cable is reeled in.

Cables are typically quicker and easier to inspect, and many large corporations require cable only for all their lifting devices.

The chain option creates a smoother lowering and raising of your load, smoother braking, as well as providing a stronger solution, therefore needing to replace your cables less often. The cable option is more useful in wet areas where moisture and rust build up is more common.

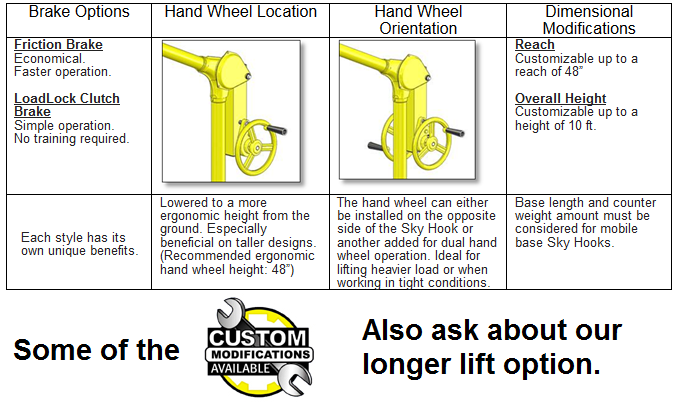

What is the difference between a friction style brake and a clutch brake?

There are two brake styles offered for the Sky Hook lifting devices. Each brake style offers specific benefits for different applications.

Friction Brake (Economy):

The standard Friction Brake utilizes the friction of a brake on a hub to hold the load applied to the hook of the Sky Hook. This brake style has a lever that protrudes from the top of the Sky Hook gearbox by the hand wheel. Using the Friction Brake is a simple one-hand operation. For the operator to raise the load he must simply rotate the hand wheel clockwise*.

To lower the load, the operator will need to slowly pull back on the brake lever while controlling the rate of descent with the palm of the same hand against the outer ring of the hand wheel. The operator can lower the load as slow, or fast, as desired. If there is a very light load or no load at all on the hook of the Sky Hook, the operator may need to either rotate the hand wheel counter-clockwise*, or pull down on the hook, while pulling back on the brake lever. If at any point the operator lets go of the brake lever, the Sky Hook will hold the load at that position.

The benefits of this brake style can be seen in that it is very economical in that it does not add any cost to the Sky Hook unit. It is also a great option for customers requiring quick operation especially when lowering the load. Customers lowering the load long distances would find it to be beneficial because of the ease of operation.

Clutch Brake (Premium - Weston Style Brake):

The Clutch Brake option uses the design concept used commonly in handchain operated chain hoists. The Clutch Brake uses mechanical screw forces to hold the load at all times. Releasing the brake is done by the operator rotating the hand wheel counter-clockwise*. There is no lever required to operate this brake. Operation of the Clutch Brake is seamless and convenient.

Raising the load with a Clutch Brake requires the operator to simply rotate the hand wheel clockwise* same as on the Friction Brake. The difference between the two brake styles is in the operation of lowering the load. Lowering the load with a Clutch Brake requires the operator to simply rotate the hand wheel the opposite direction from raising it. The brake does all the work for releasing when necessary.

If at any point the operator lets go of the hand wheel, the Sky Hook will hold the load at that position. The benefits of this brake are in simplicity. It does not require explanation to operate. Employers can trust that the Sky Hook brake will not likely be used incorrectly as the room for error is nearly non-existent. The extra cost of this brake style is easily respected with the additional ease of use it offers.