Dockplates

Aluminum dock plates are a cost effective solution for loading and unloading trucks with hand trucks, manual pallet jacks and electric pallet trucks. Aluminum dockplates generally have a maximum capacity of just under 5000lbs and are therefore not suitable for forklifts, for those you will need an aluminum or steel dock board.

Shop Reliable and Affordable Dockplates for Every Loading Need: Find the Perfect Dockplate for Your Loading Dock Only at Handtrucks2GO

Overview of Dockplates and Their Importance

Dockplates are essential tools in material handling, acting as a bridge between a loading dock and a truck or trailer. They create a smooth and safe path for moving goods across gaps, making it easier to load and unload items. Whether you’re using hand trucks, pallet jacks, or forklifts, dockplates are a key piece of equipment that enhances efficiency and safety in various industries.

In material handling, dockplates play a critical role by simplifying the transfer of goods. Without them, moving heavy or bulky items across uneven surfaces would be challenging, risky, and time-consuming. They help prevent accidents by reducing the risk of slips, trips, and falls, ensuring a secure surface for workers and equipment.

Dockplates come with several features that make them indispensable in the logistics and material handling industries:

- Durability: Typically made from tough materials like aluminum or steel, dockplates are built to withstand heavy loads and constant use, ensuring long-lasting performance.

- Portability: Many dockplates are lightweight and easy to move, allowing for quick setup and repositioning as needed.

- Variety: They are available in different sizes and capacities, catering to a wide range of loading and unloading needs.

- Safety: Non-slip surfaces and beveled edges on dockplates enhance worker safety by providing stable footing and smooth transitions between surfaces.

Overall, dockplates are crucial for improving the speed and safety of material handling operations, making them a smart investment for any business involved in logistics, warehousing, or retail.

Different Types of Dockplates to Choose From

When selecting the right dockplate, it’s crucial to understand the differences between the various types—aluminum, steel, and specialty dockplates—each offering distinct advantages for different material handling needs.

Aluminum Dockplates

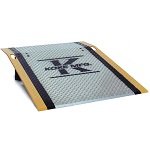

Aluminum dockplates are favored for their lightweight nature, making them easy to handle and move around. Despite their lighter build, they offer robust strength, suitable for supporting moderate to heavy loads, particularly when using hand trucks or manual pallet jacks. Their resistance to corrosion also makes them a great choice for outdoor applications or environments where moisture is a concern, ensuring longevity even in less-than-ideal conditions.

These lightweight aluminum dockplates vary from 36” to 72” wide, and in lengths from 30" up to 72”. They are available in both the 3/8″ thick, and 1/2″ thick varieties. The 1/2″ thick dock plates have higher capacities, are a bit more heavy duty and weigh more.

These light capacity dock plates are constructed from high-strength aluminum tread plate. The tread plate, or diamond plate, surface provides excellent traction and anti-slip properties.

They are ideal for use at low volume docks where mobility of the ramp is key. They are also light weight enough to be put on a delivery truck enabling the driver to be better prepared and therefore more efficient.

Steel Dockplates

Steel dockplates are the heavy lifters in the dockplate world, built to handle the most demanding tasks. They can support very heavy loads, including forklifts and other heavy machinery, making them indispensable in industrial settings. Steel dockplates are highly durable, withstanding rough treatment without significant wear and tear, which makes them a long-term investment in environments where they’ll face daily abuse. However, their heft usually requires the use of equipment for positioning, reflecting their role in more permanent, heavy-duty operations.

Specialty Dockplates

Specialty dockplates are designed to meet specific, often unique, operational needs. These might include extra-wide options for accommodating larger loads or reinforced plates for exceptionally high weight capacities. Often custom-made, these dockplates provide tailored solutions for particular industries or tasks, ensuring that all operational requirements are met. They might also feature specialized coatings or enhanced structural features, providing additional durability and performance where standard dockplates might fall short.

In summary, whether you need a lightweight, corrosion-resistant option like aluminum dockplates, a heavy-duty, durable solution like steel dockplates, or a custom-built specialty dockplate for unique needs, choosing the right type will significantly improve the efficiency and safety of your material handling operations.

A dock plate inspection should be performed every couple of weeks for any cracks or worn spots. Dock plate showing these signs of wear should be replaced.

Dockplates vs. Dock Boards

When it comes to bridging the gap between a loading dock and a truck, both dockplates and dock boards serve this purpose, but they are designed for different types of loads and equipment. Understanding their key differences can help you choose the right tool for your specific needs.

Key Differences

The primary difference between dockplates and dock boards lies in their construction and intended use. Dockplates are generally made from aluminum or steel and are designed for lighter, wheeled equipment like hand trucks and manual pallet jacks. They are flat, with no curbs, making them easier to move around and position.

On the other hand, dock boards are built to handle much heavier loads, such as those from forklifts or electric pallet jacks. Dock boards are typically made from reinforced steel and feature side curbs that prevent equipment from rolling off the sides, adding an extra layer of safety. This makes them suitable for more demanding applications where the equipment and loads are heavier and more hazardous.

When to Choose a Dockplate Over a Dock Board

You should choose a dockplate when you’re dealing with lighter loads or manual equipment that doesn't require the extra support or safety features of a dock board. For example, if your operation primarily involves moving goods with hand trucks or manual pallet jacks, a dockplate is sufficient. Its lighter weight makes it easier to move into place and store when not in use, which is ideal for smaller operations or where the dockplate needs to be frequently repositioned.

Conversely, if you are using heavy machinery like forklifts, a dock board is the better choice. The added durability and safety features, such as the raised curbs, ensure that the board can handle the weight and prevent accidents during loading and unloading. Dock boards are more permanent fixtures, often staying in one place due to their heavy weight and sturdiness, which suits environments with consistent, heavy-duty loading needs.

Conclusion

Choosing between a dockplate and a dock board depends largely on the type of equipment you use and the loads you handle. Dockplates are great for lighter, manual tasks, offering flexibility and ease of use, while dock boards are essential for heavier, more demanding operations, providing the strength and safety needed for larger equipment and loads. Understanding these differences ensures that your loading and unloading processes are both efficient and safe, tailored to the specific demands of your operation.

Dockplates for Different Vehicles

Dockplates are versatile tools designed to bridge gaps between loading docks and vehicles, ensuring smooth transitions for various types of material handling equipment. Understanding how they interact with different vehicles like hand trucks, pallet jacks, and forklifts is crucial for safe and efficient operations.

Dockplates for Hand Trucks

Hand trucks are commonly used for lighter loads, and dockplates are perfectly suited for them. Aluminum dockplates, in particular, are ideal because they’re lightweight and easy to maneuver, making them a great match for hand trucks. The smooth surface of a dockplate ensures that the small wheels of hand trucks glide over without getting caught, reducing the risk of tipping or slipping. For operations involving frequent loading and unloading with hand trucks, dockplates offer a simple and effective solution.

Dockplates for Pallet Jacks

Pallet jacks, especially manual ones, are another piece of equipment where dockplates excel. Like hand trucks, pallet jacks require a stable, smooth surface to move between the dock and the vehicle. Dockplates provide this surface, allowing the small wheels of the pallet jack to transition effortlessly across gaps. Whether you’re using a manual or electric pallet jack, dockplates are sturdy enough to handle the weight and provide the necessary stability. Aluminum dockplates work well for manual pallet jacks due to their lighter weight, while steel dockplates might be better for electric pallet jacks that carry heavier loads.

Dockplates for Forklifts

When it comes to forklifts, the demands are higher due to their weight and the heavy loads they carry. Dockplates can be used with forklifts, but there are limitations. For light-duty forklifts, a steel dockplate with a high load capacity might be sufficient. However, if you’re dealing with very heavy forklifts or loads, you might want to consider a dock board instead, which is specifically designed for heavy-duty use with forklifts. Dockplates are generally not recommended for very heavy forklifts because they may not provide the necessary durability and safety.

Dockplates are compatible with a range of vehicles, from hand trucks to pallet jacks and even light-duty forklifts. Aluminum dockplates are ideal for lighter, manual equipment, offering ease of use and portability. Steel dockplates, while heavier, are more suited to electric pallet jacks and lighter forklifts. However, for heavier forklifts, dock boards might be a safer and more durable option. Selecting the right dockplate based on the vehicles you use will ensure smooth, safe, and efficient loading and unloading operations.

After understanding the crucial role that dockplates play in material handling, it’s clear that investing in the right dockplate can make your operations smoother, safer, and more efficient. Whether you need a lightweight aluminum dockplate for quick, easy transitions with hand trucks, a heavy-duty steel option for robust use, or a specialty dockplate tailored to specific needs, making the right choice is essential. Don’t let your business fall behind—explore our range of dockplates today and find the perfect solution for your loading dock challenges. Visit our website and get started now to enhance your workflow and ensure safety at every step!